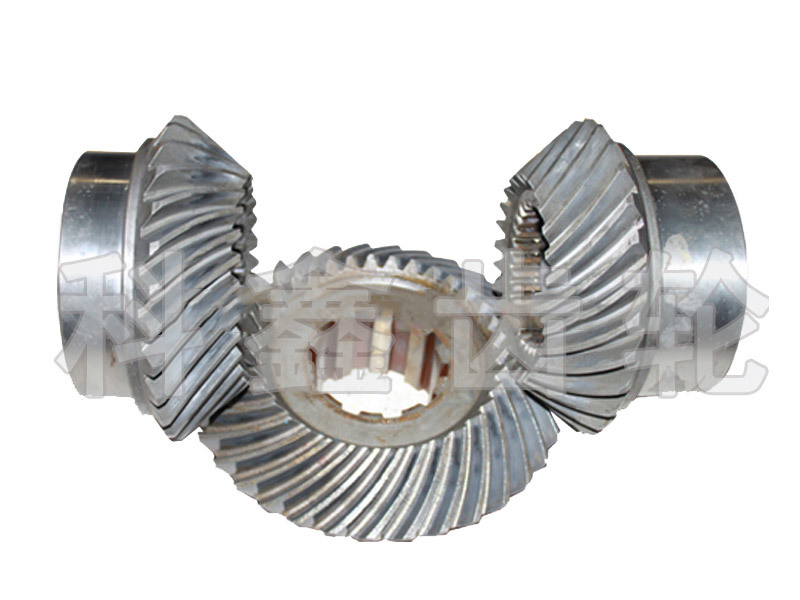

Geological drilling M8 Z26-26-36

Kexin can customize various non-standard special high-precision spiral bevel gears (Gleason teeth, Klingenberg teeth), hard-toothed cylindrical gears (straight teeth, helical teeth, herringbone without undercuts) according to customer needs. tooth) and gearbox, modulus is not limited

Key words:

Category:

Product Description

The company has a 5-axis machining center for large gears, Gleason Phoenix 600G, Gleason 800G spiral bevel gear grinding machine, Gleason P1200, Gleason P600/800 forming Gear grinding machine, Gleason P800 heavy hobbing machine, Gleason P500S gear shaping machine, and a complete set of German Ipsen heat treatment production line, supporting Gleason 1500GMM gear testing center, spectrum analyzer, metallographic analysis, ultrasonic flaw detection, maintenance There are more than 130 sets of international advanced precision testing instruments such as hardness tester, main engine and auxiliary supporting equipment.

Kexin can customize various non-standard special high-precision spiral bevel gears (Gleason teeth, Klingenberg teeth), hard-toothed cylindrical gears (straight teeth, helical teeth, herringbone without undercuts) according to customer needs. tooth) and gear box, the modulus is not limited, the maximum processing diameter is 2500mm, the grinding diameter is 1600mm, and the highest precision can reach DIN3 level.

In recent years, it has provided tens of thousands of gears and related processing parts for more than a thousand manufacturers. The customers are located in more than 30 provinces and cities across the country. The products are widely used in military industry, aerospace, shipbuilding, wind power, locomotives, mining, oil drilling, metallurgy, and medical treatment. Equipment, precision machine tools and other fields. Years of market focus have allowed us to gain industry recognition and affirmation. We have successively obtained certifications such as a member of China Machinery General Parts Industry Association, a high-tech enterprise, and ISO9001:2015 quality management system.

The Geological Drilling Spiral Bevel Gear is specifically designed for use in geological drilling equipment. It is engineered to withstand the harsh conditions and heavy loads encountered in drilling operations. These gears are made from high-strength materials to ensure durability and reliability. They are precision-machined to provide accurate gear meshing and efficient power transfer. The spiral design of the gear helps to distribute the load evenly, reducing wear and tear. Geological drilling often requires the gear to operate in dusty, wet, and high-temperature environments, and these gears are designed to handle such conditions. Their performance is crucial for the smooth and efficient operation of drilling rigs, ensuring that the drilling process can proceed without interruption.

Related Products

Product Inquiry